Biodecontamination for Pharmaceuticals & Life Sciences

Take the lead. Discover an effective way to work by using Bioquell’s tailored solutions and personalized support for bio-decontamination.

SOLUTIONS FOR LIFE SCIENCES

Pharmaceutical Manufacturing

& Compounding

You test and develop pharmaceuticals with the patient in mind. We create our complete bio-decontamination systems with you in mind. From whole-room bio-decontamination to OEM isolators for filling lines, Bioquell solutions help ensure aseptic manufacturing and compounding conditions every step of the way. Learn More

Research

& Laboratory

We understand biological safety is key to all research processes. That’s why we offer flexible bio-decontamination solutions for research facilities both large and small. At any stage of the process, our mobile and built-in systems or fully managed services allow you to help reduce the risk of contamination. Learn More

Biotechnology

& Drug Development

The strict and continual application of aseptic processing, environmental controls and monitoring are key to the success of your final drug, vaccine or product. Bioquell’s complete bio-decontamination solutions can help you maintain the integrity of your working and testing environments so you can lead the way with biological innovations. Learn More

Gene

& Cell Therapy

The high risks of microbial contamination during gene and cell manufacturing demand aseptic conditions at every step of the process. Our range of rapid and flexible bio-decontamination solutions help you create the ideal environment so you can develop and advance therapies and treatments. Learn More

FEATURED SYSTEMS

Bioquell Qube – Pharmaceutical Isolator

Take control of your environment with this modular aseptic processing workstation optimized for sterility testing, drug compounding, cytotoxic preparations and more. Learn more about this unique isolator integrated with our Hydrogen Peroxide Vapor technology using Bioquell Hydrogen Peroxide Sterilant (EPA Registration Number: 72372-1-86703).

Learn More

See for yourself the Bioquell Qube – Pharmaceutical Isolator difference

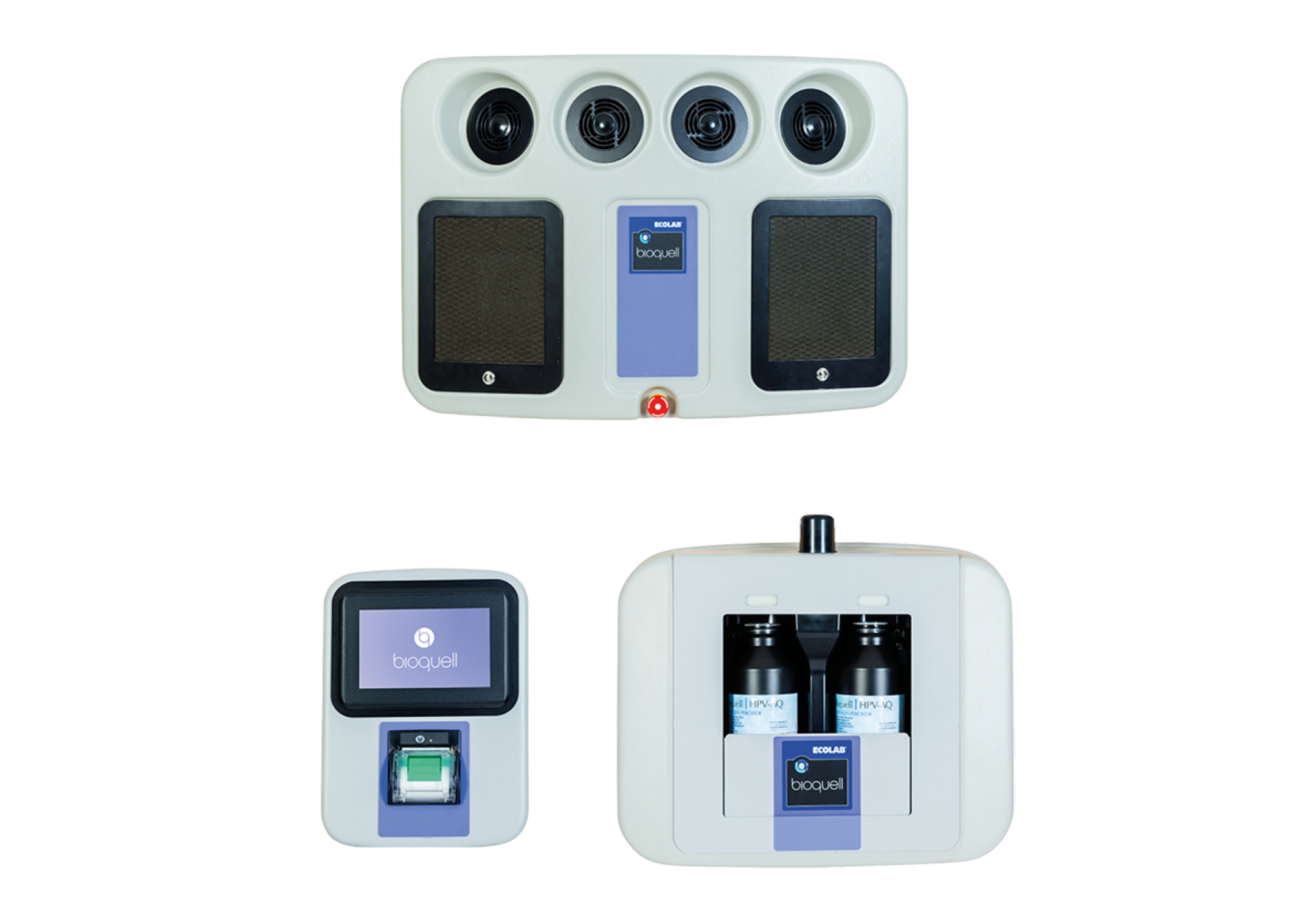

Bioquell SeQure

Our wall-mounted bio-decontamination system is ideal for pass-throughs, viral or bacterial vector work, bio-security and biological cleanrooms. See how you can help optimize your workflow with fast validation, increased productivity and regulatory compliance through an automated, validated decontamination cycle.

Learn MoreContact Us

To learn more about how Bioquell can fit your solution, please contact us.

The Americas

Ecolab Inc

702 Electronic Dr. Suite 200

Horsham, PA 19044

+1 215 682 0225

bioquellusorders@ecolab.com