From Cell Culture to Vein compliance with

Ecolab Cell and Gene Therapy Solutions

Discover the complete contamination control strategy for your company.

From the R&D phase to the clinical trials phase to the commercial production phase, partner with Ecolab to keep contamination risk under control and your operations on track.

Watch Video |Download The EBook

|Download The EBook

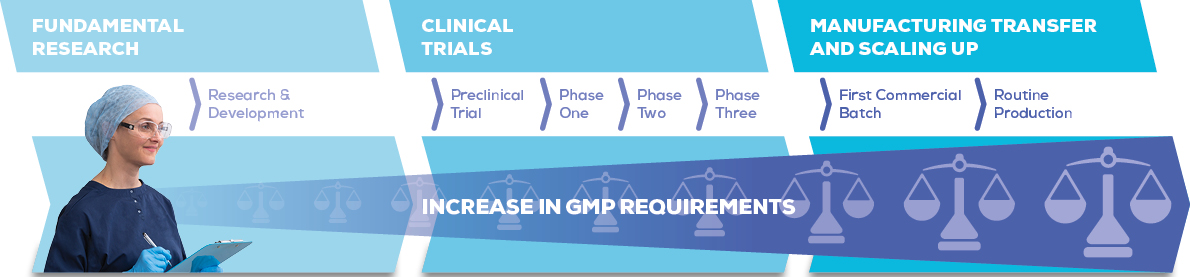

ALWAYS PLAN WITH REGULATORY COMPLIANCE IN MIND

Cell and Gene Therapy industry provides a unique regulatory challenge to navigate. Compliance very often relies on a case by case risk assessment.

Ideal for Laboratory to GMP Cleanroom

Regulation trends reflected in the recent EU GMP Annex 1 update formally recommend the use of closed systems, such as Isolators. Isolators provide a complete barrier between the process and surrounding environment, offering better in-process contamination control. The use of Isolators should be implemented early in development phase to ease transition from R&D to clinical trials and commercial manufacturing.

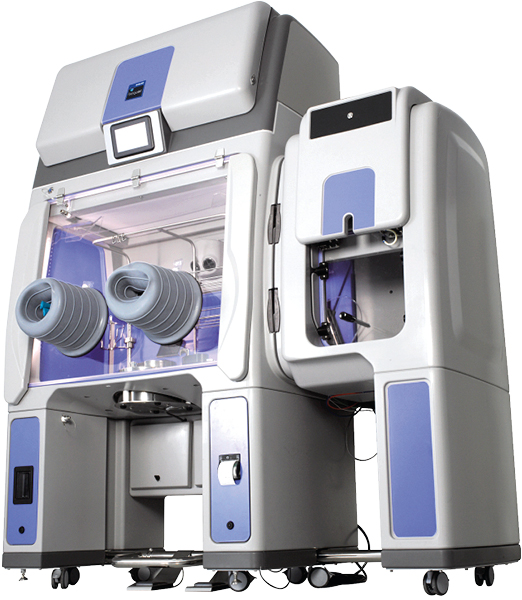

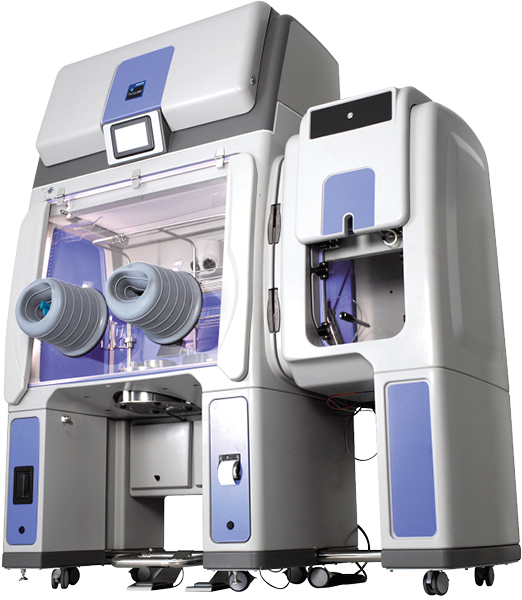

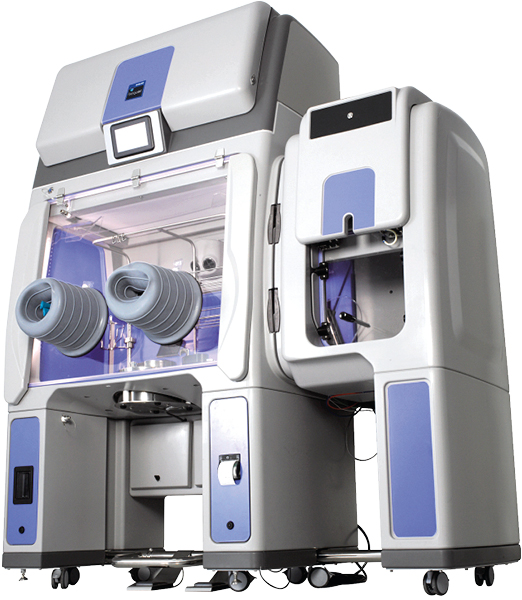

The development of novel Cell & Gene therapies such as CAR T-Cells, mRNA or stem cell therapy requires extended Research and Development activity before starting clinical trials. The Bioquell Qube is a standard, off-the-shelf isolator which provides a grade A/ISO 5 working environment without the need for complex integration into a building. This means no construction work, removal of cleanroom panels, no HVAC connections needed, and no additional electrical installations are needed. Due to its unique polyproylene construction, the Bioquell Qube can be delivered, installed and validated in as little as 16 weeks.

ECOLAB’S BIOQUELL QUBE ISOLATOR, THE IDEAL SOLUTION

“*EPA Registration Number: 72372-1-86703”

ADVANTAGES OF THE BIOQUELL QUBE ISOLATOR

SPEED

- Quick implementation and short lead time

- 6-log sporicidal kill on exposed surfaces in the isolator

- Delivery, installation, and validation in as little as 16 weeks

CONSISTENCY

- Provides Grade A / ISO 5 environment via HEPA filters and powered downflow to meet Annex 1 guidance

- Validated, automated bio-decontamination cycle with repeatable results

COST

- Cost effective due to its unique polypropylene construction

FLEXIBILITY & SCALABILITY

- Ability to expand the working space as your operations grow

COMPLIANCE

- Helps provide product consistency to assist in meeting compliance standards from regulatory bodies around the world

- EPA approved, Annex 1 compliant, and BPR approved*

*BPR, Regulation (EU) 528/2012); EPA Registration Number: 72372-1-86703

SEE THE SAVINGS

Download our case studies

Showcasing the Bioquell Qube’s impact in cell and gene therapy.

Case Study 1: See how this company saved hundreds of hours in productivity and cut energy costs.

Case Study 2: Discover how a company increased profitability while reducing batch failure and more.

VIEW THE CONFIGURATIONS

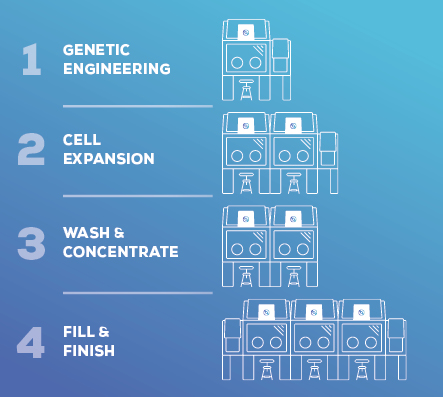

EU GMP Annex 1 recommends that an appropriate Contamination Control Strategy (CCS) is implemented to ensure compliance and patient safety. Isolator systems can create a closed process that helps mitigate the risk of contamination during all critical aseptic operations, from genetic engineering to fill/finish.

The Bioquell Qubes modularity supports your operations, from small batch production to processes requiring multiple human interactions to regulatory and quality control needs.

Find the right setup for your process with our configuration sheet.

COMPREHENSIVE SOLUTIONS FOR YOUR CLEANING AND DISINFECTION NEEDS

Cleaning and Disinfection Solutions

- Bio-decontamination equipment for rooms, equipment, pass-throughs, material airlocks and more

- Manual cleaning and disinfection

Integrated Bio-decontamination Isolators

- Bio-decontamination service option for a fully managed, scalable response for your scheduled or emergency response needs

- Bioquell hydrogen peroxide vapor bio-decontaminations connected to existing isolators and equipment

Validation Support

- Support to validate your Contamination Control Strategy according to regulation and avoid findings during audits

MORE THAN JUST CLEANING AND DISINFECTION EQUIPMENT AND SUPPLIES

- Find operational efficiencies

- Increase the total value of your process by sticking with GMP and other regulatory guidance

- Create compliance-based SOPs early for faster approvals

- Discover energy and other cost savings

- Ensure your cleaning and disinfection products are compatible with your operations

- Focus on building lifesaving products, while we handle contamination control

Learn more about Bioquell’s technology here or contact us below

Contact Us

To learn more about how Bioquell can fit your solution, please contact us.

The Americas

Ecolab Inc

702 Electronic Dr. Suite 200

Horsham, PA 19044

+1 215 682 0225

bioquellusorders@ecolab.com