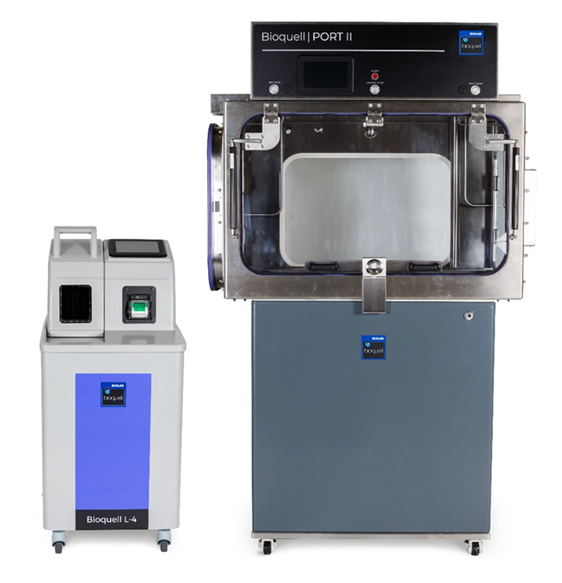

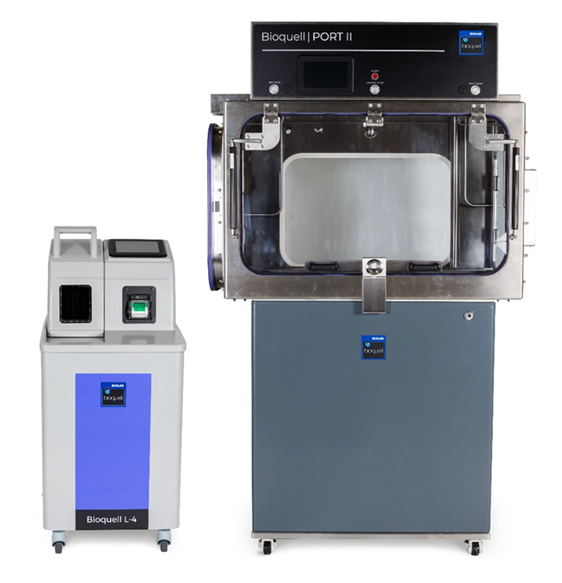

Bioquell Port II

The Bioquell Port II offers rapid, secure material transfers into aseptic environments to eliminate the risk of process contamination. Rapidly create and retain an aseptic environment by connecting the enclosure to a Bioquell hydrogen peroxide vapour system such as the Bioquell L-4. With integrated aeration, decontamination cycles in the Bioquell Port II are fast, reliable and repeatable.

Ideal for:

- Material Transfer

- Aseptic Processing

- Hospital Pharmacy Compounding

- Sterile Production Filling Lines

WHY CHOOSE THE Bioquell Port II

Rapid

Safely transfer decontaminated materials quickly

Productive

Allows for efficient just-in-time processes; high throughput

Assured

Key process parameters monitored for repeatable safe decontamination; interlocked doors eliminate potential errors

Automated

Repeatable decontamination cycles when combined with Bioquell Hydrogen Peroxide Vapour; remove operator error

Validated

Full GMP compliance; 6-log sporicidal reduction with Bioquell Hydrogen Peroxide Vapour generator option

Integrated

Fits new and existing process isolators; equipped with aeration capabilities for faster decontamination cycles

Applicable Solutions

Connect with Third Party Equipment

CONNECT WITH 3rd PARTY EQUIPMENT

ACCESSORIES

Bioquell L4

This versatile, multipurpose Hydrogen Peroxide Vapour generator can decontaminate surfaces from enclosures and equipment to larger rooms and spaces. When combined with the Bioquell Port II, you eliminate the risk of introducing a contaminant in to your process during material transfers.

This versatile, multipurpose Hydrogen Peroxide Vapour generator can decontaminate surfaces from enclosures and equipment to larger rooms and spaces. When combined with the Bioquell Port II, you eliminate the risk of introducing a contaminant in to your process during material transfers.

Our individually crafted biological indicators made from Geobacillus stearothermophilus endospores ensure reliable results when seeking to validate a 6-log reduction of bioburden from the decontamination process

VALIDATION

Each Bioquell Port II is subject to a full installation and qualification by our trained specialist engineers, including IQ, OQ and gas cycle development services. Decontamination cycles can be developed for specific loads or maximum and minimum loads to optimise cycle times whilst achieving 6-log sporicidal reduction through Bioquell’s Hydrogen Peroxide Vapour technology.

FAQs

Is an aeration unit featured in the system?

Yes. The Bioquell Port II features a powerful inbuilt catalyst for the rapid break down of hydrogen peroxide vapour.

How do you ensure all of the load receives 6-log bio-decontamination?

It is important that all surfaces of the load are exposed and occluded surfaces are minimised, Bioquell provide a number of standard and customised racking to assist with this.

Is the hydrogen peroxide vapour generator included with the system?

You will need to use a separate Bioquell L-4 generator alongside the Port II. This generator can also be used to decontaminate isolators and other equipment in your facility.

Contact Us

To learn more about how Bioquell can fit your solution, please contact us.

UK Contact

Ecolab Ltd

52 Royce Cl,

Andover SP10 3TS, UK

+44 (0)1264 835 835

bioquell.enquiries@ecolab.com